Silig Naxaas ah oo 0.05mm ah oo loogu talagalay Daadinta Gariiradda

Mabda'a shaqada ee gariiradda dab-shidka baabuurta waa in danab yar oo DC ah loo beddelo danab sare oo DC ah iyadoo la adeegsanayo rogidda iyo hagaajinta danab laba-geesood ah kaas oo si kala go' ah u dhex mara gariiradda dab-shidka. Danab sare ayaa lagu kiciyaa qaybta labaad ee gariiradda dab-shidka (Guud ahaan qiyaastii 20KV) ka dibna wuxuu ku kaxeeyaa xirka dab-shidka ee gariiradda dab-shidka si uu u daadiyo dab-shidka. Way adag tahay in la xakameeyo qaar ka mid ah sifooyinka fiilada dhaldhalaalka ah ee gariiradda dab-shidka baabuurta maadaama silig jaban uu badanaa dhaco inta lagu jiro hawsha. Iyadoo la tixgelinayo shuruudaha gaarka ah ee gariiradda dab-shidka, shirkaddayadu waxay naqshadaysaa silig dhaldhalaal ah oo loogu talagalay gariiradaha dab-shidka baabuurta oo leh muuqaal aad u fiican, alxan wanaagsan, iska caabin jilicis sare iyo xasillooni inta lagu jiro wax soo saarka. Waxaan isticmaalnaa silig naxaas ah oo la sawiray oo markii hore lagu daboolay alxanka salka heerkulka hooseeya. Kadib siliggu waxaa sidoo kale lagu dahaadhay dhaldhalaal jilicsan oo jilicsan. Qaybaha siliggan waa polyurethane oo leh iska caabin heerkul sare.

Mid ka mid ah astaamaha fiilada dhaldhalaalka ah (G2 H0.03-0.10) ee giraanta dab-shidka baabuurta waa in dhexroorkeedu aad u khafiifsan yahay. Kan ugu khafiifsan waa qiyaastii saddex meelood meel timaha aadanaha. Intaa waxaa dheer, maadaama ay tahay silig leh dhaldhalaal polyurethane qaro weyn oo heer kuleyl ah 180C, waxay leedahay baahiyo aad u sarreeya oo ku saabsan habka wax soo saarka. Shirkaddayadu waxay leedahay khibrad badan iyo tignoolajiyad bisil oo horumarsan oo ku saabsan naqshadaynta siligga dhaldhalaalka ah ee giraanta dab-shidka baabuurta. Habka wax soo saarku waa mid deggan.

1. Hagaajinta iska caabbinta jilcinta si aan loo jabin inta lagu jiro jajabinta iyadoo la raacayo xaalad ah 260℃*2 daqiiqo.

2. Waxqabadka alxanka oo ka wanaagsan, dusha sare ee alxanka waa siman oo nadiif ah iyada oo aan lahayn slag alxan oo hoos yimaada xaaladda 390℃*2S.

Heerka jabitaanka siligga ee habka wax soo saarka ayaa laga dhimay in ka badan 20% ilaa wax ka yar 1%, si dusha sare u siman yahay oo uu u socdo si deggan.

1. Waxaan qaadannaa dahaar isku dhafan: dhaldhalaalka oo leh hanti alxan heerkul hooseeya ayaa loo isticmaalaa sidii dahaar saldhig ah, dhaldhalaalkana wuxuu leeyahay iska caabin jilcisa oo sare sida dahaarka sare si loo soo saaro silig dhaldhalaal ah oo isku dhafan oo leh alxan wanaagsan iyo iska caabin jilicis sare leh.

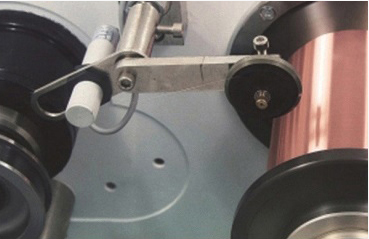

2. Hagaajinta tiknoolajiyada wax soo saarka ee siligga dhaldhalaalka ah: isbeddelka xoogga saliidda sawir-qaadista inta lagu jiro sawir-qaadista. Qalabka loogu talagalay maaraynta wax soo saarka ayaa ku habboon dusha sare ee siligga naxaasta ah. Rakibaadda qalabka hagaajinta viscosity-ga otomaatiga ah iyo qalabka xakamaynta xiisadda otomaatiga ah ee habka dhaldhalaalka ayaa yareeya heerka jabka siligga.

| Iska caabinta 20 °C | Dhexroorka | Tolrance | ||

| (mm) | (mm) | |||

| Tirada (ohm/m) | Ugu yaraan (ohm/m) | Ugu badnaan (ohm/m) |

|

|

| 24.18 | 21.76 | 26.6 | 0.030 | * |

| 21.25 | 19.13 | 23.38 | 0.032 | * |

| 18.83 | 17.13 | 20.52 | 0.034 | * |

| 16.79 | 15.28 | 18.31 | 0.036 | * |

| 15.07 | 13.72 | 16.43 | 0.038 | * |

| 13.6 | 12.38 | 14.83 | 0.040 | * |

| 11.77 | 10.71 | 12.83 | 0.043 | * |

| 10.75 | 9.781 | 11.72 | 0.045 | * |

| 9.447 | 8.596 | 10.3 | 0.048 | * |

| 8.706 | 7.922 | 9.489 | 0.050 | * |

| 7.748 | 7.051 | 8.446 | 0.053 | * |

| 6.94 | 6.316 | 7.565 | 0.056 | * |

| 6.046 | 5.502 | 6.59 | 0.060 | * |

| 5.484 | 4.99 | 5.977 | 0.063 | * |

| 4.848 | 4.412 | 5.285 | 0.067 | * |

| 4.442 | 4.042 | 4.842 | 0.070 | * |

| 4.318 | 3.929 | 4.706 | 0.071 | ±0.003 |

| 3,869 | 3.547 | 4.235 | 0.075 | ±0.003 |

| 3.401 | 3.133 | 3.703 | 0.080 | ±0.003 |

| 3.012 | 2.787 | 3.265 | 0.085 | ±0.003 |

| 2.687 | 2,495 | 2.9 | 0.090 | ±0.003 |

| 2.412 | 2.247 | 2,594 | 0.095 | ±0.003 |

| 2.176 | 2.034 | 2.333 | 0.100 | ±0.003 |

| 1.937 | 1.816 | 2.069 | 0.106 | ±0.003 |

| 1.799 | 1.69 | 1.917 | 0.110 | ±0.003 |

| 1.735 | 1.632 | 1.848 | 0.112 | ±0.003 |

| 1.563 | 1.474 | 1.66 | 0.118 | ±0.003 |

| 1.511 | 1.426 | 1.604 | 0.120 | ±0.003 |

| 1.393 | 1.317 | 1.475 | 0.125 | ±0.003 |

| 1.288 | 1.22 | 1.361 | 0.130 | ±0.003 |

| 1.249 | 1.184 | 1.319 | 0.132 | ±0.003 |

| 1.11 | 1.055 | 1.17 | 0.140 | ±0.003 |

| 0.9673 | 0.9219 | 1.0159 | 0.150 | ±0.003 |

| 0.8502 | 0.8122 | 0.8906 | 0.160 | ±0.003 |

| 0.7531 | 0.7211 | 0.7871 | 0.170 | ±0.003 |

| 0.6718 | 0.6444 | 0.7007 | 0.180 | ±0.003 |

| 0.6029 | 0.5794 | 0.6278 | 0.190 | ±0.003 |

| 0.5441 | 0.5237 | 0.5657 | 0.200 | ±0.003 |

| Dhexroorka | Tolrance | Silig naxaas ah oo la isku dhejiyay (dhexroor guud) | |||||

| (mm) | (mm) | Fasalka 1aad | Fasalka 2aad | Fasalka 3aad | |||

|

|

| Ugu yaraan (mm) | Ugu badnaan (mm) | Ugu yaraan (mm) | Ugu badnaan (mm) | Ugu yaraan (mm) | Ugu badnaan (mm) |

| 0.030 | * | 0.033 | 0.037 | 0.038 | 0.041 | 0.042 | 0.044 |

| 0.032 | * | 0.035 | 0.039 | 0.04 | 0.043 | 0.044 | 0.047 |

| 0.034 | * | 0.037 | 0.041 | 0.042 | 0.046 | 0.047 | 0.05 |

| 0.036 | * | 0.04 | 0.044 | 0.045 | 0.049 | 0.05 | 0.053 |

| 0.038 | * | 0.042 | 0.046 | 0.047 | 0.051 | 0.052 | 0.055 |

| 0.040 | * | 0.044 | 0.049 | 0.05 | 0.054 | 0.055 | 0.058 |

| 0.043 | * | 0.047 | 0.052 | 0.053 | 0.058 | 0.059 | 0.063 |

| 0.045 | * | 0.05 | 0.055 | 0.056 | 0.061 | 0.062 | 0.066 |

| 0.048 | * | 0.053 | 0.059 | 0.06 | 0.064 | 0.065 | 0.069 |

| 0.050 | * | 0.055 | 0.06 | 0.061 | 0.066 | 0.067 | 0.072 |

| 0.053 | * | 0.058 | 0.064 | 0.065 | 0.07 | 0.071 | 0.076 |

| 0.056 | * | 0.062 | 0.067 | 0.068 | 0.074 | 0.075 | 0.079 |

| 0.060 | * | 0.066 | 0.072 | 0.073 | 0.079 | 0.08 | 0.085 |

| 0.063 | * | 0.069 | 0.076 | 0.077 | 0.083 | 0.084 | 0.088 |

| 0.067 | * | 0.074 | 0.08 | 0.081 | 0.088 | 0.089 | 0.091 |

| 0.070 | * | 0.077 | 0.083 | 0.084 | 0.09 | 0.091 | 0.096 |

| 0.071 | ±0.003 | 0.078 | 0.084 | 0.085 | 0.091 | 0.092 | 0.096 |

| 0.075 | ±0.003 | 0.082 | 0.089 | 0.09 | 0.095 | 0.096 | 0.102 |

| 0.080 | ±0.003 | 0.087 | 0.094 | 0.095 | 0.101 | 0.102 | 0.108 |

| 0.085 | ±0.003 | 0.093 | 0.1 | 0.101 | 0.107 | 0.108 | 0.114 |

| 0.090 | ±0.003 | 0.098 | 0.105 | 0.106 | 0.113 | 0.114 | 0.12 |

| 0.095 | ±0.003 | 0.103 | 0.111 | 0.112 | 0.119 | 0.12 | 0.126 |

| 0.100 | ±0.003 | 0.108 | 0.117 | 0.118 | 0.125 | 0.126 | 0.132 |

| 0.106 | ±0.003 | 0.115 | 0.123 | 0.124 | 0.132 | 0.133 | 0.14 |

| 0.110 | ±0.003 | 0.119 | 0.128 | 0.129 | 0.137 | 0.138 | 0.145 |

| 0.112 | ±0.003 | 0.121 | 0.13 | 0.131 | 0.139 | 0.14 | 0.147 |

| 0.118 | ±0.003 | 0.128 | 0.136 | 0.137 | 0.145 | 0.146 | 0.154 |

| 0.120 | ±0.003 | 0.13 | 0.138 | 0.139 | 0.148 | 0.149 | 0.157 |

| 0.125 | ±0.003 | 0.135 | 0.144 | 0.145 | 0.154 | 0.155 | 0.163 |

| 0.130 | ±0.003 | 0.141 | 0.15 | 0.151 | 0.16 | 0.161 | 0.169 |

| 0.132 | ±0.003 | 0.143 | 0.152 | 0.153 | 0.162 | 0.163 | 0.171 |

| 0.140 | ±0.003 | 0.151 | 0.16 | 0.161 | 0.171 | 0.172 | 0.181 |

| 0.150 | ±0.003 | 0.162 | 0.171 | 0.172 | 0.182 | 0.183 | 0.193 |

| 0.160 | ±0.003 | 0.172 | 0.182 | 0.183 | 0.194 | 0.195 | 0.205 |

| 0.170 | ±0.003 | 0.183 | 0.194 | 0.195 | 0.205 | 0.206 | 0.217 |

| 0.180 | ±0.003 | 0.193 | 0.204 | 0.205 | 0.217 | 0.218 | 0.229 |

| 0.190 | ±0.003 | 0.204 | 0.216 | 0.217 | 0.228 | 0.229 | 0.24 |

| 0.200 | ±0.003 | 0.214 | 0.226 | 0.227 | 0.239 | 0.24 | 0.252 |

Transformer-ka

Matoorka

Gariiradda shidista

Codka gariiradda

Koronto

Relay

Macaamiisha oo ku jihaysan, Hal-abuurku wuxuu keenaa Qiimo badan

RUIYUAN waa bixiye xal, kaas oo naga doonaya inaan xirfad badan u yeelano fiilooyinka, agabka dahaarka iyo codsiyadaada.

Ruiyuan waxay leedahay dhaxal hal-abuur leh, oo ay weheliso horumarka fiilooyinka naxaasta ah ee la dhalaaliyay, shirkaddayadu waxay kortay iyada oo u heellan daacadnimo, adeeg iyo jawaab celin macaamiisheenna.

Waxaan rajeyneynaa inaan sii wadno kobaca ku salaysan tayada, hal-abuurka iyo adeegga.

7-10 maalmood Celcelis ahaan waqtiga keenista.

90% macaamiisha Yurub iyo Waqooyiga Ameerika. Sida PTR, ELSIT, STS iwm.

Heerka dib-u-iibsiga 95%

Heerka Qanacsanaanta 99.3%. Alaab-qeybiyaha Heerka A waxaa xaqiijiyay macaamiil Jarmal ah.